IsoTool Results

What are the options to isolate a pipeline to replace aged and leaking valves?

Many of our projects involve providing isolation so buried valves can be brought above grade.

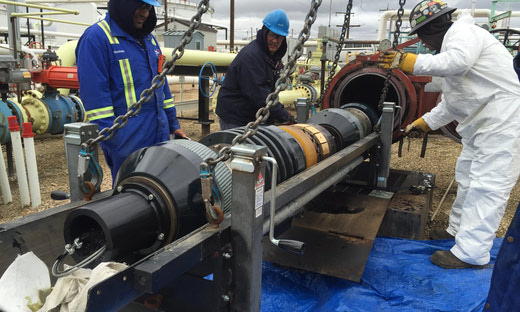

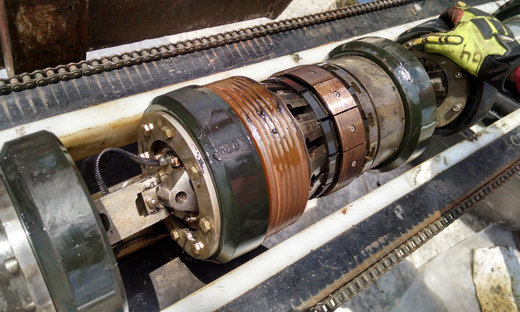

Integral Pipeline Technologies has integrated using its IsoTool with nitrogen purging to greatly reduce the purge length, while simultaneously displacing the product in the cut out section.

For most pipelines it is critical that they maintain constant flow, some even more so

One of our regular clients had a 20” receive valve and a 16” launch valve leaking in the same yard.

A launch valve on an 80 year old pipeline was showing its age and needed to be replaced.

Many comments were made about how much simpler this method was than conventional means.

A small leak is no small matter. A hinge pin on a check valve had a minor leak that needed to be addressed.

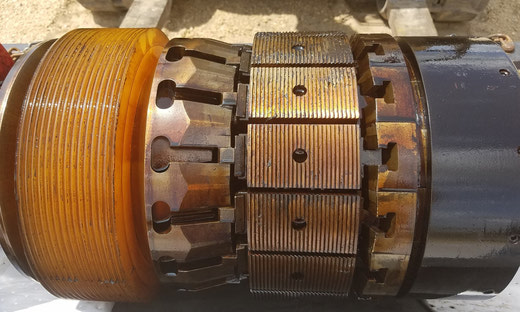

Integral is pleased to announce that Enbridge has been added to the growing list of pipeline operators who have utilized the IsoTool.

The client approached Integral about utilizing the IsoTool to provide isolation of a 20” condensate pipeline to facilitate the replacement of the gates and seals in the 16” trap bypass valve and the 20” trap mainline valve.

The client wanted to replace all the valves at the launch and receive trap, in a single pig run the 12” IsoTool isolated both the launch and receive traps to allow for 19 new valves to be installed.

Integrals 18” IsoTool provides isolation for a leaking trap valve in its inaugural run. The client wanted to replace a leaking launch valve and trap bypass valve on a gasoline pipeline.

The client had a leaking trap valve, we configuring the IsoTools to allow for bi-directional travel often provides a smart option when replacing leaking trap valves.

The Department of Transportation decided to relocate a bend in an Interstate that had frequent fatalities. This required a pipeline crossing to be re-routed using an HDD, the pipeline company employed the IsoTool to perform an IsoPurge

In a ground breaking project, Integral Pipeline Technology utilized the IsoTool to the dual purpose of purging and isolating a 20” pipeline for the removal of a span of pipe over a water crossing.

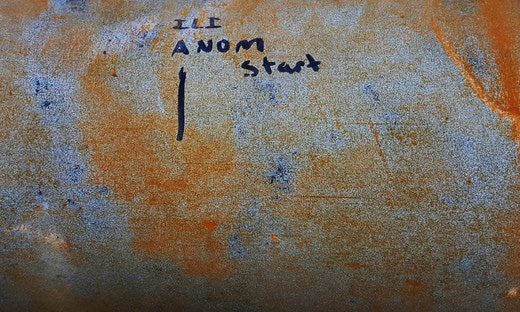

A long seam defect was detected by an In-Line Inspection tool, and the client’s integrity program required that it be removed, two 10” IsoTools were launched and tracked 27 miles

A 24” receiving trap valve with a known leaking stem needed to be replaced, the IsoTool was configured to allow for bidirectional travel and pumped against normal flow direction

A section of 20” with a known anomaly required removal for verification of the defect, the IsoTools were launched 200’ apart and tracked 101 miles to the repair site

Configured to be bi-directional, the Integral IsoTool was used to isolate a 10” pipeline launcher in North Dakota, a leaking launch valve was an integrity conc

A new delivery point was required along an existing pipeline at a newly constructed tank farm, two 24” IsoTools were deployed to isolate the line and allow the tie in of the new valves and delivery laterals.

Two 16” IsoTools were deployed to Northern Alberta to facilitate a mainline valve replacement project. The IsoTools were specially configured to traverse a known restriction in the pipeline.

A single IsoTool was deployed to South Texas to assist in a trap valve replacement project. The scope of the project involved launching the IsoTool using nitrogen so the pig was built with zero by-pass to facilitate a gas launch.

A single IsoTool was deployed to assist in a 3 valve replacement project. Due to uninterruptible well production, draining up or purging the line would have created an outage that jeopardized shutting in the well at great cost to the producer.